Building the MintyBoost

Although my own homemade Band Aids Battery Pack still works fine with newer iPods (and just about anything else that charges via a car adapter), I still wanted to try to build the very popular and ingenious MintyBoost charger, which was invented and thoroughly documented by Limor Fried (aka ladyada) on Instructables and then later updated on her own website. I had written about it when it first came out but couldn't use it at the time since my 3G iPod would only charge via firewire. The advantage of the MintyBoost is that it only uses 2 AA batteries and charges via the iPod's USB cable. Due to Apple's varying implementation of USB requirements over time, no USB charger seems to work with every iPod let alone every USB device out there.

Now that I have an 8 GB 3G nano with video that charges via a USB cable, I thought I would try my hand at putting together a do-it-yourself electronics kit.

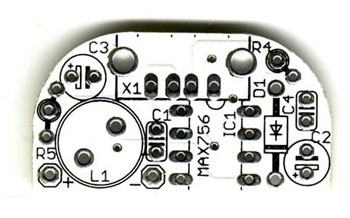

Though Limor says the MintyBoost is an easy project, this is in comparison to her other much more complicated projects. The challenge with the MintyBoost is the circuit board is very small (not much larger in area than a quarter) and crammed tightly with components in order to fit in the space left over after you put a 2-AA battery holder in an Altoids gum tin. I counted 32 different solder joints required. I have never really been able to solder anything. In 8th grade shop class I tried to solder a TV scrambler and I think I burned out a transistor because it never worked right. I kind of soldered some wires onto the lighter socket for my Band Aids project, but I didn't do a very good job. So the first thing I needed to do was learn to solder. I studied Limor's site thoroughly last weekend, reading the soldering tutorials, watching the online videos (very, very helpful), and reading her instructions. Then I bought all the right tools including the right type and diameter of solder, a Weller soldering iron (I learned that a 40-watt iron isn't really better than a 25-watt one), a vise to hold the project, and a "third hand" to hold whatever else I might need. Because I was worried about messing up, I also bought a solder sucker to help remove solder, and a length of soldering wick to also remove solder (I didn't end up using them and don't know how much use they would have been anyway but they were cheap).

Everything but the vise (backordered) arrived from one of Limor's recommended sellers, Electronix Express. It turns out I should have at least bought the soldering iron from Home Depot because Weller makes kits in two different packages. In addition to a standard tip, one includes a needle nose point for small electronics (like this project) and the other includes some bigger points for wood burning, which is what I wound up with. I was still able to get by with the standard tip, but Home Depot had both kits and for only $10 vs. $18 (I had tried Ace Hardware, but the store I visited was out of the kit and I kind of wanted the extra tips and stuff that came with the kit).

I got a decent deal on Altoids gum at Walgreens drug store where they had a buy-one-get-one-free special, but they only had peppermint flavor. So I had an extra tin in case something goes wrong (the gum is pretty good at first, with a crunch super minty shell like you would expect but the flavor fades pretty quickly and the gum itself isn't that good).

I was glad to get the kit from Limor when I did because she was down to her last few. However I checked on her inventory the next day and she had 45 kits in stock. A day or two later she was down to 27. She sells tons of these things! She can get pretty good prices by buying electronics in volume (and tells you where she gets the parts and how much they are in case you want to get them on your own) and then adds in profit. The key is getting her circuit board. Again, she gives you files where you can make your own if you have the equipment, but hers is very good quality and already cut to the right size. The whole kit is $19.50 but you can buy the board by itself for $5. Postage is extra but only a few dollars, so I paid $22.68 for one kit. It arrived quickly in a padded envelope with all of the components in a static-free bag sealed with a sticker with her logo and a link to her instructions page. She doesn't sell completed kits because she really wants people to try out soldering on their own. In addition to the instructions she has discussion forums that she checks on pretty frequently.

Once I got the soldering iron, I had everything I needed except the vise. However I figured I could use the third hand to hold the work. So I could have saved some money by just getting that ($2.95, whereas the vise is $19.95). I practiced soldering by placing the cold tip on components and touching the solder to it. Then I tried soldering a couple of paper clips together just to get the hang of heating the work rather than the solder. I'm not so great at soldering paper clips. I also tried to desolder the paper clips by using the pump and the wick with very little success.

Despite that, I thought I could go ahead and try soldering the first three components onto the board. I had downloaded her page on soldering the pieces and followed it to the letter. When I first got the kit, I had put all the pieces on there just to make sure everything fit but couldn't solder them yet. But now I put the pieces in and bent the leads like she said so the pieces would stay in place with the board upside-down. Because the pads are very small, even with 0.031 inch diameter solder wire, it doesn't take much to finish the joint. It worked pretty much like it was supposed to. As long as the tip touches both the lead wire and pad on the circuit board they will heat up enough to melt the solder. And the solder will flow all over the pad and down the hole on its own.

The two biggest keys are not to overheat and not to oversolder. If the solder doesn't melt within about a second or two, then take the iron off of the work, let it cool a little and try placing the tip of the iron all over again. Maybe you need to reposition the work or reach it from a different angle this time. You definitely don't want to oversolder because removing the excess isn't easy and if you spill onto an adjacent pad, you will short everything out. If you undersolder, you could potentially add a little more later, though really you want to just do it once and get it right. In the end I had a few places that could probably use a little more solder, but I think the connections are still easily good enough. Step-by-step I kept adding components and soldering them in place. As recommended, I put the resistor, R5, in the "pull up" position (which works for my nano) which connect the two USB data pins to the positive terminal via the resistor. Soldering the USB clips was the best part because you got to really add a bunch of solder to those big joints with very little danger from overheating. I had some long nose pliers to clip the leads, but they didn't let me get in close enough. I ended up leaving the leads long until I was done and then went to Home Depot to get some side cutting snips instead which worked much better (they had one pair for $13, but I wound up buying a 15-piece kit of all kinds of pliers and two adjustable wrenches including a regular-size and mini pair of side cutters for only $20).

Once I was done, I tested out the circuit just as the instructions said to and, sure enough, I got 5.03 volts of output. That was a big moment of truth. I checked again and then connected my iPod which gave a charge indication in the top right of the screen. Holding down Pause to turn the iPod off, it immediately showed the active charging icon. Yay!

One thing I wasn't crazy about with Limor's tutorial was cutting down the side of the Altoids tin to make a notch that the USB port would slide down into. Instead I wanted to cut a hole, which would leave the rim along the top of the tin intact. I was able to do this by putting a piece of masking tape on the end of the tin, marking the size of the hole, and then drilling two small holes on each end of where the hole was supposed to be (the masking tape can be drawn on but also keeps the drill bit from slipping on the metal surface). Then I used larger and larger drill bits to enlarge those holes, using the previous holes as guides. Once I was done I kind of drilled out the leftover middle and then bought a small triangular file that let me form the corners. It turned out to be the most work of the whole project getting that just right and it still turned out a little rough. Limor's method is easier, but I think mine turned out better. The key is to place the hole so that the top of it is up as high as possible. Otherwise the USB port sticks out in a downward direction. Although the instructions don't call for it and I didn't do it, I think it would be a good idea to cut out some pieces of electrical tape and put them in the rounded corners of the tin as well as the bottom of the tin where the circuit board goes just to make sure none of the wires, leads, or whatever touch the tin and potentially short something out. Of course there is no problem if the USB port touches the tin and in fact it could be soldered in place (I haven't done this because I want to be able to remove the board, plus the double-stick foam tape holds it pretty securely anyway).

This was fun and easier to make than I thought it would be. The soldering only took an hour and could take far less if I knew what I was doing. Now that I have the equipment, I would like to make more of these. I thought maybe I could make them and sell them through my web page and maybe on eBay. One person sells them for $30. Although the kit is $20, if you are buying in quantity, you can get the parts directly from the same suppliers Limor uses (she sells the circuit boards for $5 by themselves and even tells you the prices she is paying) for less than $15 including the Altoids tin. If I sold them for $25 I could make $1,000 by building and selling 100 of them. However I would also have to lay out $1,500 up front to get all of the parts.

Comments (3)

I want to build one. I have two tin boxes. I'll need to come over and use your stuff.

Posted by Jeb | December 16, 2007 9:37 PM

I need 100 psc of mintyboost version 1.2 or 1.1 pcbs. Can you make them for me.

Posted by Dilisi Seneviratne | March 18, 2009 11:02 AM

For that quantity, I could probably build them for about $25 each, but would need to receive most of the payment in advance through PayPal.

Posted by UT | March 18, 2009 9:12 PM